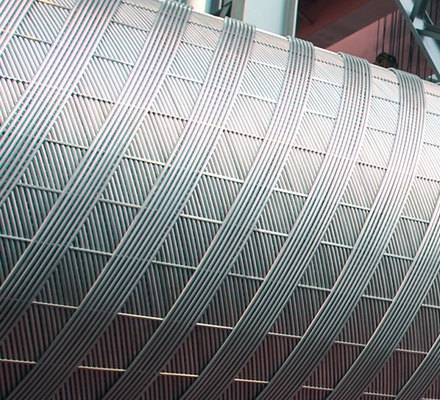

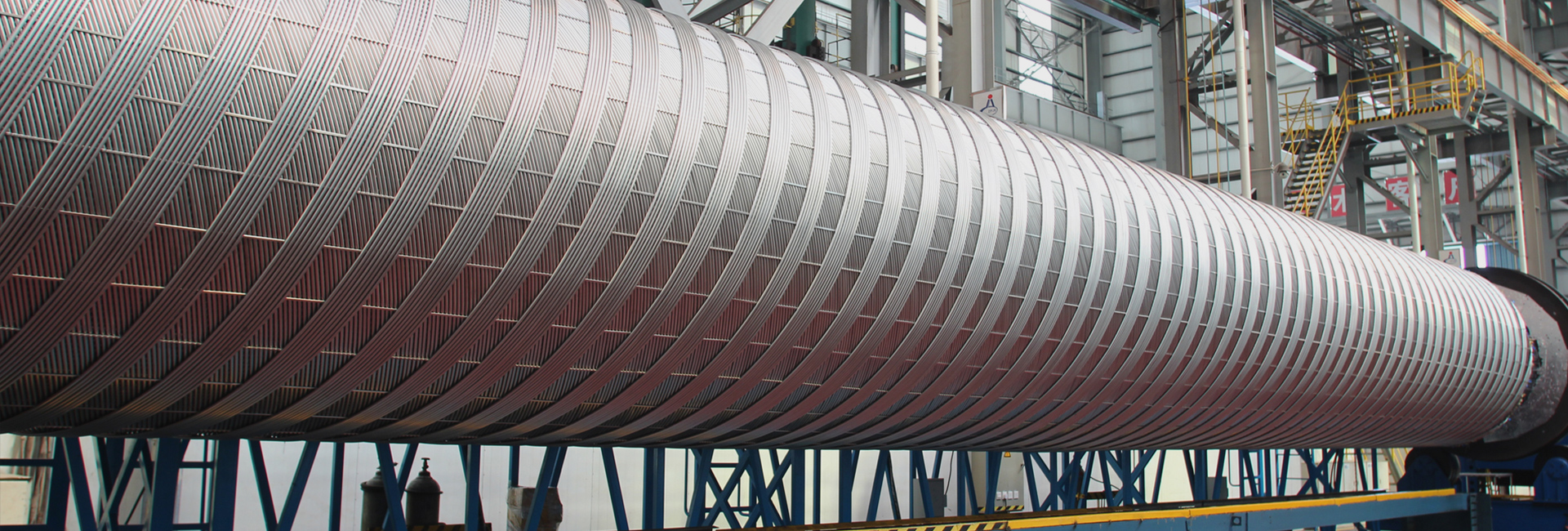

Spiral Tube Heat Exchanger

30 Years of Expertise

Spiral Tube Heat Exchanger

30 Years of Expertise

Spiral Tube Heat Exchanger

30 Years of Expertise

42 references

31 in operation

Total installed capacity >135 MMTA

>43,000 days of cumulative operation

13 years of operation in Isomerization

High efficiency allowing hot approach temperature of less than 30°C

High resistance to pressure and temperature fluctuations

Long-term stable operation

Easily mechanically and chemically cleanable.

105 references

88 in operation

Total installed capacity >125 MMTA

>150,000 days of cumulative operation

15 years of operation in CCR

High efficiency allowing hot approach temperature of less than 30°C

High resistance to pressure and temperature fluctuations

Long-term stable operation

Easily mechanically and chemically cleanable.

224 references

172 in operation

Total installed capacity >175 MMTA

>315,000 days of cumulative operation

17 years of operation in hydrotreatment

High efficiency allowing hot approach temperature of less than 10°C

large heat transfer area reducing plot area

High resistance to pressure and temperature fluctuations

Long-term stable operation

Easily mechanically and chemically cleanable.

Customer Feedback

What People Say About ZPJE?