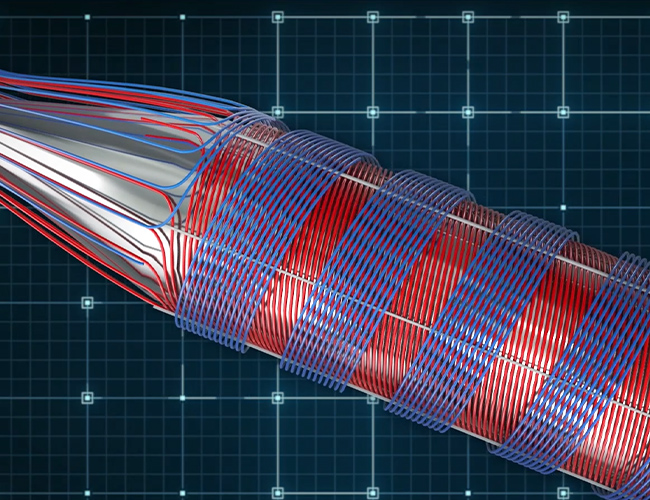

The spiral tube design improves the fluid flow regime by creating high turbulence inside and outside of the tubes. This allows for a low pinch point, reducing consequently the hot and cold approach temperatures of the exchanger.

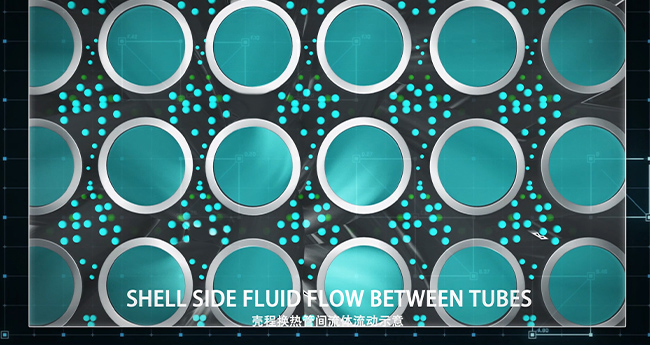

The unique tube bundle design optimizes significantly the fluid flow both on tube and shell sides, lowering the pressure drop down to only 2-3 kPa on shell side on specific processes.

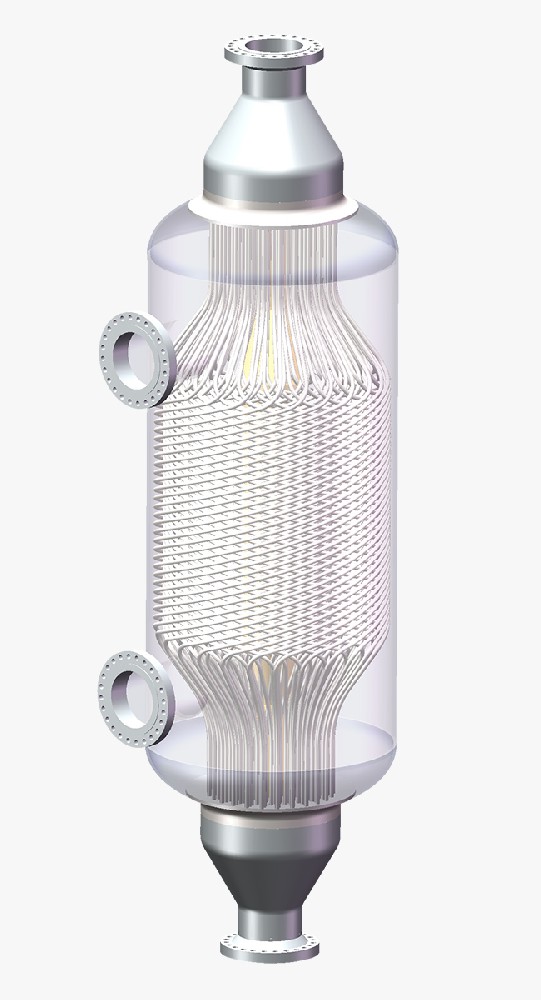

Only one exchanger can replace multiple horizontal or vertical exchangers, saving on installation and capital cost for both new units or revamping projects.

Compared to traditional shell & tube exchanger, STHE has smaller volume and weight due to its high heat transfer efficiency.

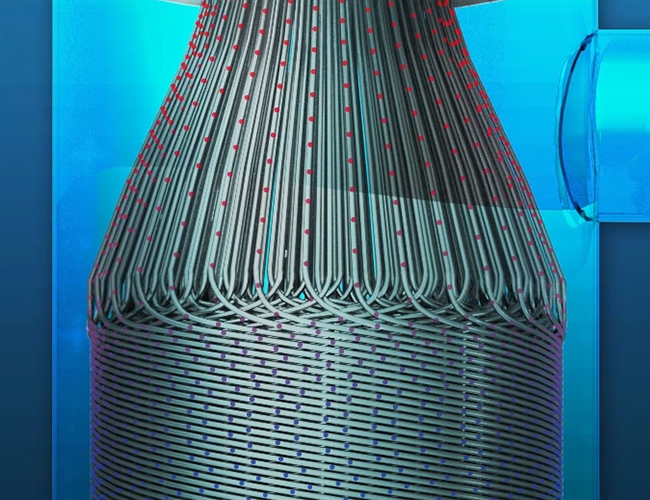

The spiral wound tube bundle offers high tolerance to thermal and pressure variations that may happen during upset conditions. The flexibility given by the spiral wound tube bundle allows:

high temperature gradients inside the exchanger

no limitation for cooling and heating rates during startup, shutdown and upset conditions

high tolerance to thermal and/or pressure shock

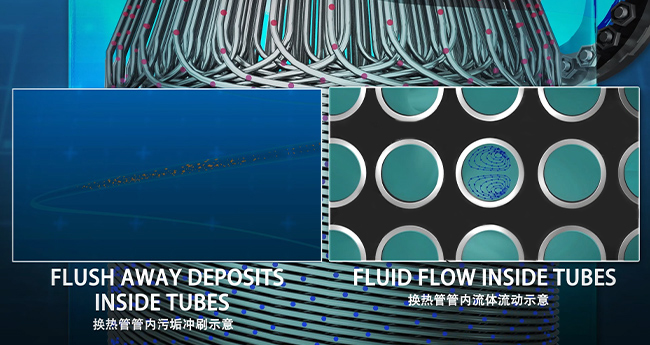

On the shell side, the high turbulence created by the pulse-surge collision flow pattern and the absence of stagnant zone greatly reduces the possibility of fouling.

On the tube side, the helix-pattern flow creates a secondary flow which increases the shear force. This effect, added to the very low surface roughness, gives an anti-fouling and self cleaning design.